Page 1 of 1

torque specs???

Posted: 01:49 am Nov 27 2010

by Budget_89KDX

I just assembled my kips in the jug and after a good deal of studying the installation pics and 3 failed attempts I finally got it right and after all was said and done it wasn't too bad.I think I was over thinking it and spooked myself but anyhoo its together and works like a charm on the bench.

So now I'm about to reassemble and had a few questions first what is the head nuts torque specs,second what is the 4 jug nuts torque specs,and third how do you properly torque the jug nuts?I have "crowes feet" are they exceptable to use to torque with?if so. What do the specs change to?I've seen in alldata when I worked for ford that usingcrowes feet were exceptable but they had a seperate torque spec if used.thanks in advance.

Posted: 02:45 pm Nov 27 2010

by Budget_89KDX

Am I to assume no one uses torque specs?

Posted: 02:55 pm Nov 27 2010

by Indawoods

No... most people have a sevice manual that has those specs in in it. Those are out in the garage and it is cold out. Or they have them online like what is posted above which they paid for.

I know you want to go cheap but a manual is a must if you want to work on your own bike. It more than pays for itself over and over again.

Posted: 03:16 pm Nov 27 2010

by Mr. Wibbens

I don't see crows feet working that great. I'd think clearance might be an issue

18 ft lbs

BTW you type like a fuggin 2 year old

Posted: 03:57 pm Nov 27 2010

by Indawoods

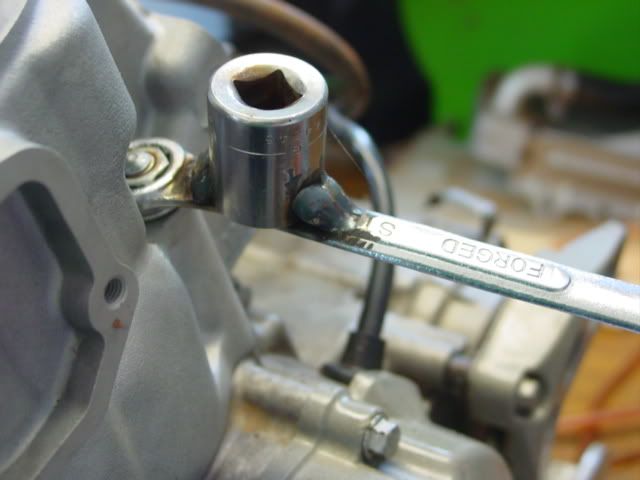

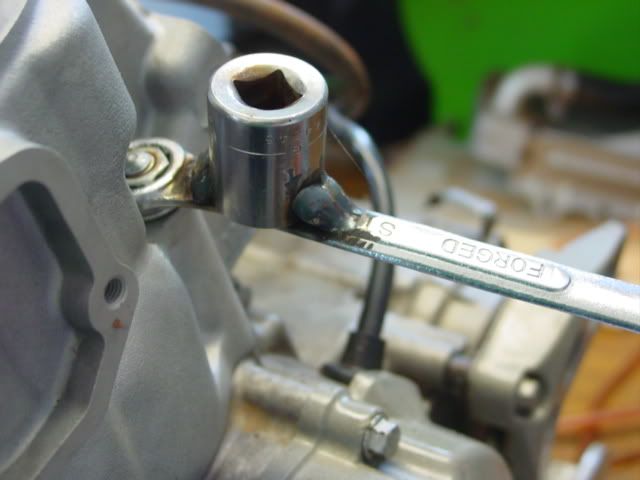

You will need the Motion Pro torque wrench extension for the jug nuts.

Posted: 04:32 pm Nov 27 2010

by Tedh98

If you have a welder or access to one, you can make your own extension out of a cheap wrench and socket.

Posted: 05:03 pm Nov 27 2010

by Budget_89KDX

So if I don't have that tool or a welder what then?

Posted: 05:10 pm Nov 27 2010

by Indawoods

I guess you will be guessin.

Posted: 05:20 pm Nov 27 2010

by kdxmaniac

hell........i never "torqe" my head and cylinder anyway..... i just tighten them down by feel, and ride the piss out of them...........just dont use a 2 ft bar on them......

btw......just built my 300 this week, has 240lbs compression, runs like a stripped ape, and didnt "torqe" the bolts.......just tighten them, and go ride.

Posted: 05:20 pm Nov 27 2010

by Mr. Wibbens

I guess

Posted: 05:22 pm Nov 27 2010

by Indawoods

kdxmaniac wrote:hell........i never "torqe" my head and cylinder anyway..... i just tighten them down by feel, and ride the piss out of them...........just dont use a 2 ft bar on them.

Me too... but I don't recommend it. People are different.

Posted: 05:24 pm Nov 27 2010

by Johnkdx200

>|QBB<[/url]

Budget_89KDX wrote:So if I don't have that tool or a welder what then?

Try and find one on craigslist?

Posted: 07:45 pm Nov 27 2010

by Budget_89KDX

Came to town and a buddys got a mig rig so I just made one.he and I were wondering won't this throw the torque off?I'm using a snap-on digital torque wrench brand new so I know its dead on.

Posted: 07:50 pm Nov 27 2010

by Budget_89KDX

[quote="Mr. Wibbens"

BTW you type like a fuggin 2 year old[/quote]

Bite me I'm on a cell phone and used to texting! Lol

Posted: 07:52 pm Nov 27 2010

by Klammer

Torque the same size bolt thats out in the open with a socket to the spec your looking to achive. Then test the same bolt with your welded tool and see what reading you get. Now you can torque the barrel nuts to that reading.

Posted: 08:03 pm Nov 27 2010

by kdxmaniac

are we stiiiiilllllll talking about torqing them there bolts???

.......id already be RIDING the bike by now!!

Posted: 10:00 pm Nov 27 2010

by Budget_89KDX

Yea I planned to test to see if its off any but thought someone would know already.

Btw what's the difference between that torque wrench setup and using a crow foot?not much difference imo.thanks though ill have it together tonight.

Posted: 10:10 pm Nov 27 2010

by Indawoods

Don't know how you would get the crows foot on it to begin with and get any kind of torque on it since it wouldn't turn at all...

Posted: 11:18 pm Nov 27 2010

by rbates9

IMO the torque isn't as important as getting them even. You could be off a few pounds ether way and probably wouldn't have a problem if they are all the same. Heat makes things move. If every thing has the same limits it will move evenly. And I could not agree more with the others, BUY A MANUAL........

Posted: 03:27 am Nov 28 2010

by Budget_89KDX

Motors done!went together without a hitch.still got 200psi checked it all out and as soon as the new pipe gets here ill be ready to ride just in time to put it up for winter.lol

Thanks for the help I will be investing in a manual asap.btw that tool was a great idea.